Products – New

Products

Since it’s beginning 65 years ago, Toyo Jidoki (PACRAFT Company Ltd.) has been an industry Ieader. As part of this gIobaI organization, PACRAFT America has brought TYJ’s standards onto American soil and can confidentIy state that no other company has our breadth of experience in designing and manufacturing pre-made pouch fiII-and-seaI equipment. Our ongoing research and deveIopment efforts have continually produced a wide range of fiII-and-seaI machines, incorporating enhanced food safety, resource efficiencies, and diverse packaging features.

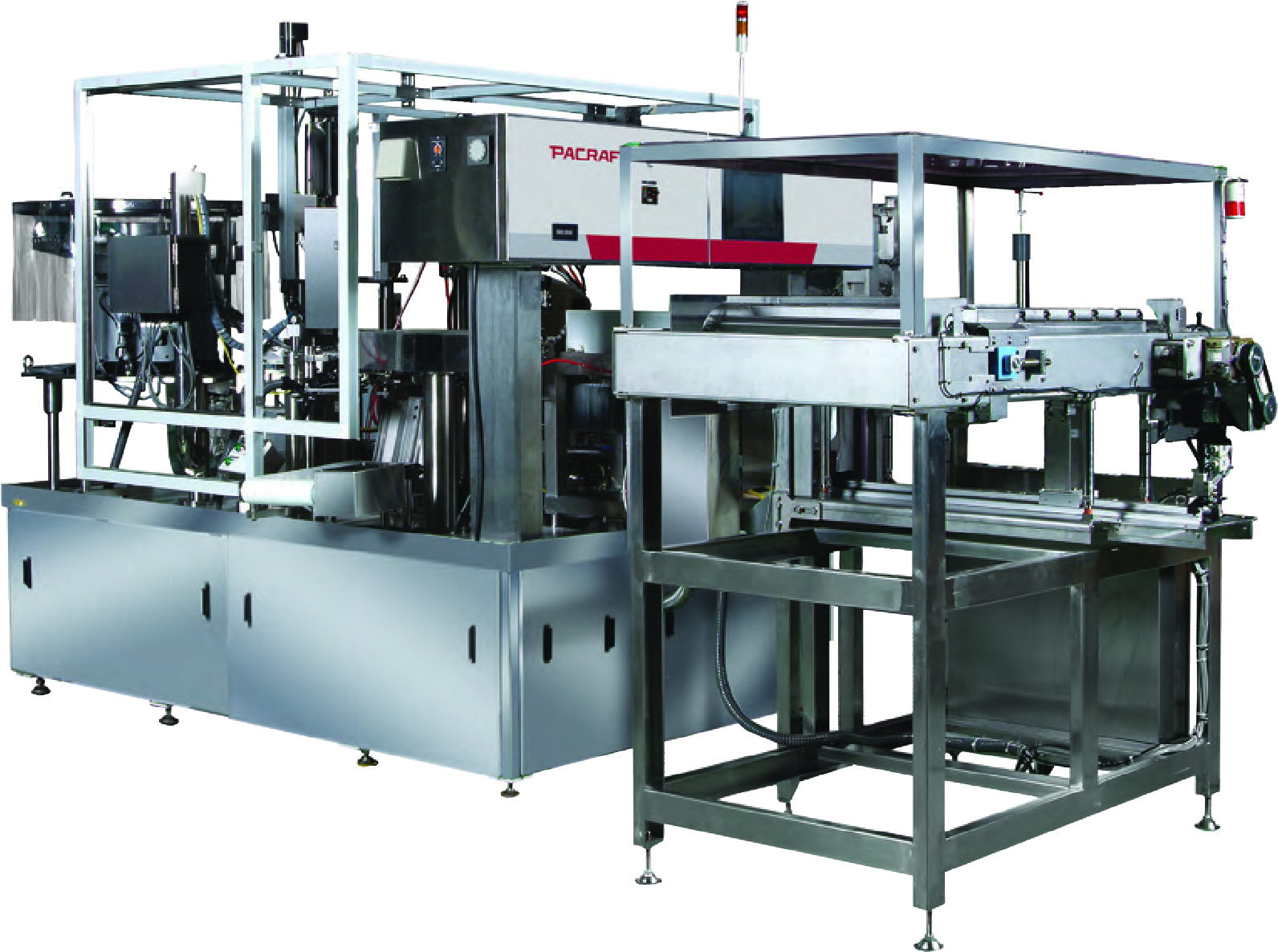

TT-8D-N

Pre-Made Pouch Fill/Seal

Confectionery, Snacks, Pet Food, Granular, Powders, and Frozen Fruit. Flexibility to handle small to medium size pre-made pouches. Eight (8) station, sanitary construction, easy to clean. Machine Speed: Up to 55 PPM

TT-8DW-N

Duplex/Twin High-Speed Fill/Seal

Twin/duplex for dry, solid, and frozen product applications – Confectionery, Snacks, Pet Food, Granular, Powders, and Frozen Fruit. Flexibility to handle small to medium size pre-made pouches. Eight (8) station, sanitary construction, easy to clean. Machine Speed: Up to 80 PPM

TT-8A2

Large Format Pre-Made Pouches

Pet Food, Coffee, Snacks, Confectionery, Granular, and Frozen Fruit. Flexibility to handle flat or gusseted stand-up pouches with optional gas flush feature available. Sanitary construction, easy to clean. Eight (8) station. Machine Speed: Up to 50 PPM.

TVP-E4

Vacuum Packaging for Pre-Made Pouches

Vacuum and retort packaging for ready meals, pickles, meat, tuna, protein, and pet food.

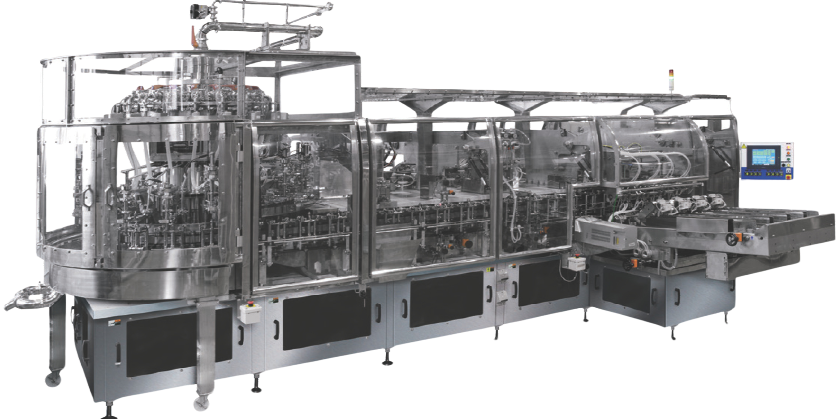

TL-AX2

High-Speed Automatic Packaging

The TL-AX series offers a wide variety of solutions for high speed, pre-made pouch packaging. In addition to food packaging and wet pet food, Pacraft offers ‘spout pouches’ filling & capping capabilities Machine Speed: Up to 250 MPH

TT-9CW

Side Gusset, Pre-Made Pouch Filling & Sealing

Offers the ability to run side gusset, pre-made pouches with standard flat-bottom or Stand-up Pouch format. Four-gripper design to efficiently maximize pouch opening. Funnel dives into pouch for no-spill filling. Nine (9) station. Machine Speed: Up to 45 PPM

TT-10CWS

Pre-Made Pouch Packaging

Rice, pet food, and coffee. Shelf stable ready meals, sauces, detergents.

TT-15CW-10

Spout Pouch Filling & Capping System

Pre-made Spout Pouch Filler and Capping system for liquids; including, Juice, Oils, Sauces, Dressings, Detergents, and more.

Popular Options & Other Machine Solutions

Pouch Vacuum Packaging

Machines

- High temperature vacuum packaging

- Small and long length pouch vacuum packaging options

- Gas Flush

- Horizontal product infeed interface capabilities

- Duplex model for higher output speeds

Specialty Machinery & Custom Applications

- Cup Filling

- Tray Filling

- Twist Tie Applicator

- Twin Pouch Filling & Sealing

- Manual, Semi-Automatic and Lab Machine models for limited production output

Pacraft Global:

A World of Solutions

Providing the most comprehensive selection of automatic filling and packing machines.